EconomicRoll – the solution for various applications

Versatile: EconomicRoll® can be used as a winder roller, deflector roller or tension roller, spacer roller or as a design element.

Strong: The special construction with a reinforced inner ring allows direct bearing inside the EconomicRoll®. Of course, other bearing types are possible for these rollers, in line with your wishes.

Precise: The modern and technically well-designed geometry of the EconomicRoll® guarantees excellent concentricity (deviation according to the sample test report of just a few hundredths of a millimetre) extremely precise concentricity is guaranteed thanks to the fine alignment.

Wear-resistant: Thanks to a standard Eloxal layer ex warehouse, your roller has wear and surface protection at no extra cost.

Fast: Thanks to smooth-running quality bearings in combination with our EconomicRoll®, high speeds and/or rpm with very precise running qualities can be achieved

Inexpensive: Due to direct bearings inside the tube, no bases or blanks are produced for your rollers - this is how we save time and you money.

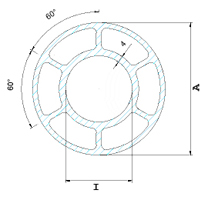

Light: A honeycomb profile with bars between the inside and outside tube generates force at very low weights.

Our EconomicRoll® is used in the

- Paper industry: Guide rollers, driven rollers, winders

- Printing industry: For instance, paper and film are winded, guided, coated and printed using the EconomicRoll® or dried across goods stores and then cut or punched.

- Textile industry: Rolled goods are flanged, coated or printed, dried across goods stores and stored intermediately, sewn and cut.

- Timber industry: Lamination systems: Thin film is laminated onto the wood, for example wooden furniture.

- Conveyor equipment: Economic Roll® as a deflector roller.

- Special machine engineering: All applications where the media needs to be guided, driven or deflected precisely.

The formats of our EconomicRoll®:

- Diameters from 60 bis 200 mm

- Lengths from 5.500 bis 7.000 mm

The surface structure of our EconomicRoll®:

- Standard: bare, smooth Rz

- Alternative: tripped, grooved, blasted, ground, convex, concave, diamond grooved, notched

The surface coating of our EconomicRoll®:

- Standard: anodised E6/EV1 and bare

- Alternativ: hard anodised, rubber-coated, bright chrome, hard chrome, ceramics, non-stick. Other surface coatings on request.

| Coating type | Properties |

|---|---|

| Eloxal | Corrosion-resistant protective layer. The standard layer thickness is 10-20 µm. Roughness depth Rz 6-8 µm |

| Hard Eloxal | More corrosion-resistant and wear-resistant than Eloxal. The layer thickness is 50+/ -10 µm. Roughness depth to customer specifications. 500-600HV |

| Chrome | Extremely high wear protection for even very small Rz values by polishing. Up to 1,000HV. |

| Ceramic | Very high wear protection at up to 1,300HV. Resistant to friction and sliding wear. Permanent traction properties or sliding behaviour. |

| Non-stick | Non-stick properties and wear protection are important criteria wherever a gentle and smooth material flow is specified. Increasing the wear resistance reduces the amount of maintenance required. This means less machine standstills and improved productivity. |

| Rubber coating | We have a large selection of various rubber coatings, e.g. for grip, with non-stick, wear protection, electrical conductivity, antistatic etc. Our rubber coating list: NR, SBR, EPDM, NBR, XNBR, CR, FPM, CSM, ACM, PU, HNBR, CO-ECO and MQ,SILICON |

The benefits of our EconomicRoll® at a glance:

- Versatile

- Direct bearing inside the tube

- Precise concentricity

- Wear and surface protection

- High speeds/RPM

- Inexpensive

- Lightweight

- Smooth running

EconomicRoll® cross section

| ER 60 | ER 80 | ER 100 | ER 120 | ER 140 | ER 160 | ER 200 | |

|---|---|---|---|---|---|---|---|

| External diameter | 60 k13 + 0,46 mm | 80 k13 + 0,46 mm | 100 k13 + 0,54 mm | 120 k13 + 0,54 mm | 140 k13 + 0,63 mm | 160 k13 + 0,63 mm | 200 k13 + 0,72 mm |

| Internal diameter | 31 ± 0,25 mm | 40 ± 0,3 mm | 53 ± 0,3 mm | 60 ± 0,3 mm | 60 ± 0,3 mm | 60 ± 0,3 mm | 77 ± 0,3 mm |

| Wall thickness inside | 4,0 mm | 4,0 mm | 4,0 mm | 4,0 mm | 4,5 mm | 5,0 mm | 5,0 mm |

| Wall thickness outside | 3,0 mm | 3,0 mm | 4,0 mm | 4,0 mm | 4,5 mm | 5,0 mm | 4,5 mm |

| Weight | 3,0 kg/m | 4,2 kg/m | 6,2 kg/m | 7,6 kg/m | 9,9 kg/m | 12,7 kg/m | 14,8 kg/m |

| Concentricity | 0,2 mm/m | 0,2 mm/m | 0,3 mm/m | 0,3 mm/m | 0,4 mm/m | 0,4 mm/m | 0,4 mm/m |

| Material | AIMgSi 0,5 | AIMgSi 0,5 | AIMgSi 0,5 | AIMgSi 0,5 | AIMgSi 0,5 | AIMgSi 0,5 | AlMgSi 0,5 |

| Surface | eloxiert E6/EV1 | eloxiert E6/EV1 | eloxiert E6/EV1 | eloxiert E6/EV1 | eloxiert E6/EV1 | eloxiert E6/EV1 | eloxiert E6/EV1 |

| Moment of inertia l× | 325.300 mm4 | 808.400 mm4 | 1.969.700 mm4 | 3.436.700 mm4 | 5.995.530 mm4 | 9.816.000 mm4 | 17.981.300 mm4 |

| Moment of resistance Wx | 10.850 mm³ | 20.210 mm³ | 39.394 mm³ | 57.278 mm³ | 85.650 mm³ | 122.700 mm³ | 179.810 mm³ |

| E = 6.900 | daN/mm² | ||||||